Development of a gentle milk protein fractionation process

The Hungarian Dairy Research Institute (HDRI) is at the forefront of the development of membrane separation methods (microfiltration, ultrafiltration, nanofiltration, reverse osmosis) for use in the dairy industry to create new products and production technologies which result in the better utilisation of milk components.

Our research and development efforts brought about new products—milk protein concentrates and isolates, cheese products, whey protein-based cream cheeses and desserts, micellar casein and native whey protein isolates—which, with their favourable nutritional values, excellent sensory and functional properties, and advantageous materials input, contribute to the prosperity of the dairy industry. Products made with these procedures are manufactured both in Hungary and abroad. Apart from product and technology development, our portfolio includes the design of production lines and special manufacturing equipment, the installation of production lines, and the definition of quality control requirements the application of which guarantees production safety and that high-quality products are made.

The two main components of milk protein, that is, casein and whey protein differ in many characteristics, their composition, and nutritional value. The four major membrane separation techniques (microfiltration, ultrafiltration, nanofiltration, reverse osmosis) and their combinations offer a number of theoretical and practical options for the physical separation and concentration of milk components. These procedures have the benefit of retaining native proteins and preserving their physico-chemical structures and original properties.

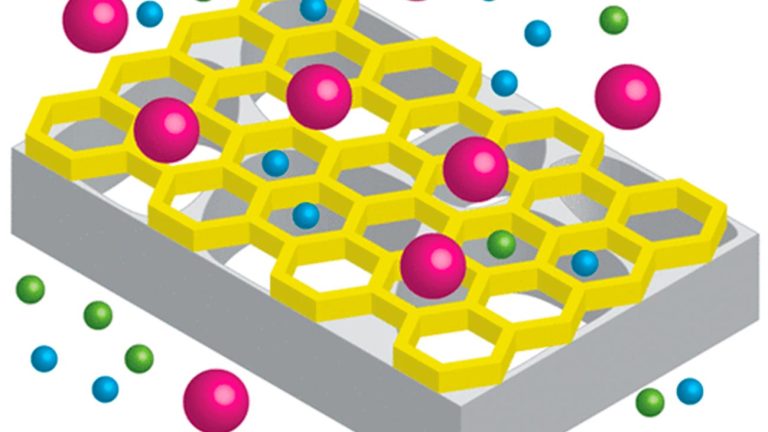

During microfiltration, different pressures are applied on the two sides of a semipermeable membrane so the molecules of a size smaller than the pores of the membrane can pass through but not the bigger molecules which concentrate. The material that passes through the membrane is called permeate and the material that remains on the input side is called retentate or concentrate. When milk is microfiltered, casein concentrates in the retentate and the whey protein fractions of a smaller molecule size penetrate the membrane and settle in the permeate.

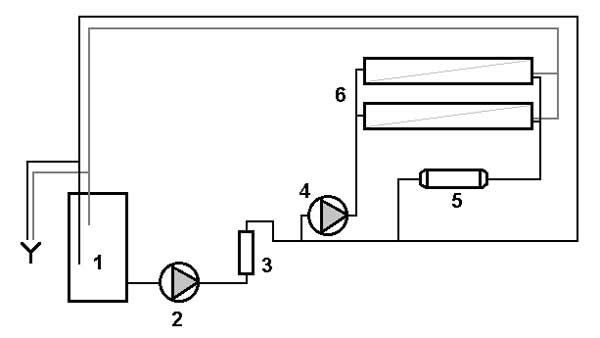

The greatest drawback of the current technique of warm microfiltration (at 45–50 ºC) is that typically, operation time cannot exceed 8 hours because microorganisms proliferate during the process. Cold microfiltration (at 10–20 ºC) is an innovative solution on a global level developed by the Institute. Permitting a longer operation time, cold microfiltration is more economic on an industrial scale (relatively shorter washing time and fewer chemicals needed, better utilisation of equipment capacity, longer membrane lifetime because of cold operation). Its disadvantage compared to warm microfiltration is that the filtration capacity (flux) of the membranes drops at a lower temperature, hence a larger membrane surface is necessary.

Due to the higher temperature, the biological value of milk proteins decreases during warm microfiltration, and the food materials thus produced are of a poorer quality in terms of nutrition and health benefits. The retentate generated by cold microfiltration is of higher microbiological purity and it contains native milk proteins. Moreover, this gentle method yields products with great added value. It promises considerable economic benefits; complex production technologies using cold microfiltration are therefore expected to draw strong interest.

The Institute sought to reach a casein ratio of 95 % within the retentate’s protein content; it is a challenging endeavour because whey proteins become less mobile at the temperature used for cold microfiltration. Raising the casein ratio to the maximum possible level is very important as the products made from high-purity casein concentrate are in great demand on the global market thanks to their thermal stability, which makes them a good choice for the production of various nutraceuticals.

The permeate generated by cold microfiltration, the “ideal whey”, contains native whey proteins and is practically free of germs, fat, protein decomposition products, additives and rennet residuals, and is thus a suitable component of whey protein ingredients of an exceptional quality.

With targeted experiments, we defined the optimal parameters of cold microfiltration such as:

- membrane type (e.g., material, nominal pore size),

- temperature,

- pressure,

- volume reduction,

- rate of diafiltration.

We found that filtration capacity (flux at 50 ºC tended to be 2 to 2.3 times higher on average than at 15 ºC) decreased in cold microfiltration. The higher the volume reduction, and consequently, the protein content of the microfiltered retentate, the lower the filtration capacity. The protein content of the retentate in the dry matter was at least 80 per cent, and its casein ratio did not fall below 95 per cent in the total protein content.

In addition, we established the permeability of the different types of membranes used for cold microfiltration, the physico-chemical and microbiological properties of the concentrates produced, and the retention values of the membranes for each macrocomponent of milk.

To specify the permeability of the different types of membranes used for cold microfiltration, we used the polymeric spiral membranes of two manufacturers well-known in the food industry. Based on the actual and apparent retention values calculated from the results, we concluded that protein retention was somewhat higher at 15 ºC than at 50 ºC, for both membrane types; however, this is only a slight difference. The average microbiological proliferation of the germ groups examined was one order of magnitude smaller in cold microfiltration at 15 ºC as opposed to microfiltration done at 50 ºC, for both membrane types.

Cold microfiltration is more cost-efficient and requires less energy and fewer chemicals than other techniques currently in use. The byproducts generated during the procedure can be processed using other membrane separation methods (nanofiltration, reverse osmosis). When subjected to proper physical treatment, the water thus obtained from milk can be used as a component in dairy products or for the cleaning and disinfection of equipment and rooms. This leads to substantially fewer byproducts and, as a result, facilitates environmental sustainability.