There is a growing interest from both the dairy industry and consumers for milk-derived ingredients such as Micellar Casein Concentrates (MCC) and Whey Protein Concentrates (WPC) with targeted protein profiles for nutritional or functional purposes.

The pilot-scale dairy plant at the Hungarian Dairy Research Institute Ltd. (HDRI) in Mosonmagyaróvár (Hungary) is designed and equipped to develop new, unique and tailor-made food ingredients for the dairy industry to meet consumers’ demands, as well to develop new production methods and technologies that best fit the processors’ needs.

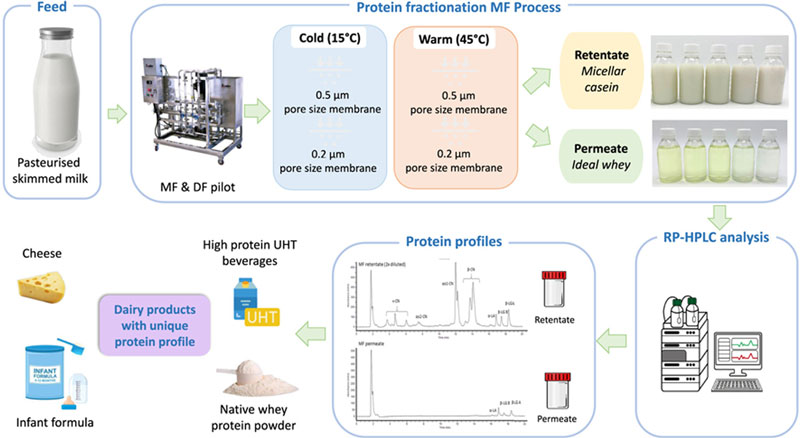

One of the main research areas of HDRI is the fractionation and enrichment of certain milk protein fractions using various filtration technologies. The production technology is based on cold microfiltration process, which is less widespread in the industry. The intermediate products enriched with a specific protein fraction provide the basis to produce new functional foods with high added value.

In research we investigated the influence of membrane pore size and filtration temperature on six individual milk protein fractions (αS-CN, β- CN, κ-CN, α-LA, β-LG A, β-LG A) during the protein fractionation microfiltration process. Pasteurised skimmed milk was microfiltrated using two different pore sizes of spiral-wound membranes, with pore sizes of 0.2 μm and 0.5 μm, at temperatures of 15 °C and 45 °C respectively. The microfiltration process was carried out with a final volume reduction of 66% and a diafiltration volume of 120% (300 L) of the original feed (250 L).

It was observed that neither the pore size nor the filtration temperature significantly (p < 0.05) affected the permeation of the α-LA fraction. However, the permeation of the β-LG A and β-LG B fractions can be influenced by membrane pore size and filtration temperature, and the behaviour of the three whey protein fractions, A and B genetic variants of the β-LG and α-LA fractions differ significantly during the microfiltration process.

The research demonstrated that the three main whey protein fractions have a different behaviour during the protein fractionation microfiltration process. The permeation of the β-LG A and β-LG B fractions can be influenced by membrane pore size and filtration temperature. These findings could help to produce micellar casein and ideal whey with a unique protein profile and could lead the dairy industry in a new direction to produce new tailor-made protein ingredients such as alpha-lactalbumin rich, beta-lactoglobulin poor permeate, which could also be used as an ingredient in infant formula.

Authors:

Henrietta Buzás, Gábor Szafner, Mónika Krassóy, Aline Wiedmann, Attila József Kovács